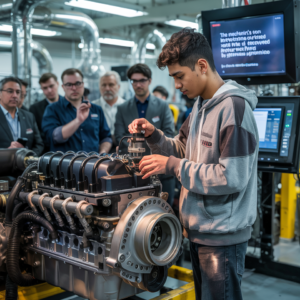

“You think you can fix this?” the CEO asked. His tone was half-mockery, half-dare.

The boy — just 19, wearing oil-stained jeans and a secondhand hoodie — looked up from the open engine with calm eyes. The entire engineering team watched in awkward silence. They had spent three weeks trying to restart the company’s custom-built, multi-million-dollar prototype engine. And now, out of desperation — or ego — the CEO had handed a wrench to a teenager.

He was the son of their retired head mechanic, a man who’d fixed tanks and turbines but never wrote a single line of code. The boy, Mateo Reyes, had no degree. No badge. Just a strange confidence that unsettled the room.

“Give me twenty minutes,” he said.

People chuckled. The CTO rolled her eyes.

But then, something happened.

Mateo didn’t reach for manuals. He didn’t ask for schematics. He just listened — ear near the turbine, fingers feeling the rhythm of the frame like a pianist sensing a broken key.

And then, he started to work.

Not randomly — intuitively. Rerouting a fuel bypass valve no one knew existed. Tapping a hidden sensor module. Whispering numbers to himself like he was solving an ancient puzzle in another language.

Seventeen minutes later, the engine purred.

Not sputtered. Not groaned. It purred — as if relieved that someone finally understood it.

And then it happened: the diagnostics flashed green — and a secret module the engineering team hadn’t even unlocked suddenly came online. The engine wasn’t broken. It was unfinished. What they thought was a flaw… was actually a gate. Mateo had completed it.

The CTO stared at him. “How did you know?”

He shrugged.

“My dad used to hum the same rhythm when he worked. I thought maybe the machine was humming back.”

Legacy in the Steel

Mateo Reyes had never seen the inside of a university, but he grew up surrounded by engines that whispered their secrets.

His father, Ramon Reyes, was a legend in the old-world mechanical circles — the kind of man who never raised his voice, but could make broken machines “confess” with a wrench and a patient hand. Ramon served 28 years as the head mechanic of Aether Dynamics, a rising aerospace startup with military ties and billion-dollar ambitions.

“I never saw him open a laptop,” said Chris Devlin, a senior engineer. “But if your jet rotor was two millimeters off, he’d hear it before you did.”

Mateo was six when he started shadowing his father at the hangar. Not playing. Watching. Absorbing the way his dad spoke to machines, not in words — but with rhythm, patience, trust.

“He always said machines have language,” Mateo would later recall.

“But you have to shut up long enough to hear them speak.”

When Ramon retired after a health scare, Mateo disappeared from the hangar. No one expected to see him again — certainly not in the middle of a crisis.

A $500 Million Failure, Until It Wasn’t

The VORTEX engine — a revolutionary fusion prototype — was the company’s crown jewel. Designed for vertical cargo aircraft and deep-orbit drones, it promised emission-free thrust at 20% the weight of traditional combustion.

Then it failed.

Three weeks.

Twelve senior engineers.

Four consulting firms.

No fix.

The engine booted. But it refused to engage its primary core. Diagnostics called it a “faulty ignition vector.” But no one could locate the failure. It wasn’t hardware. It wasn’t code.

They were out of ideas.

And that’s when Mateo arrived — supposedly to drop off his dad’s old tool chest.

Instinct Over Instruction

Mateo didn’t ask for permission. He didn’t demand attention. He simply looked… curious. And when he asked to take a look, people laughed. The CEO handed him a wrench with a smirk.

Then he listened.

“There was this moment,” said Jenna Luo, the CTO. “Where he crouched down and just touched the housing like it was alive. It wasn’t mechanical. It was personal.”

Mateo sensed something no one else did — a rhythm.

A subtle pulsing loop that reminded him of something his father used to hum. That same hum his dad used when calibrating hydraulics, or when threading wiring through tight junctions.

“I thought… what if the engine’s not broken? What if it’s just waiting for the right beat to unlock itself?”

That’s when he typed the forgotten command:

/r.ray_legacy/init_heartbeat

A test script. Buried in an old directory. No one remembered it. But someone had built it — Ramon Reyes.

The moment it ran, the machine woke up.

And in doing so, it revealed something else: a latent AI calibration subroutine that no one had ever seen. A learning system that only initialized if the proper “heartbeat pattern” was recognized — likely a private failsafe Ramon had coded and never documented.

Mateo didn’t just fix a bug. He completed the design.

The New Rules

Mateo turned down a full-time position.

He said he wasn’t ready — not yet. He wanted to build his own path, not be absorbed by the system. But before leaving, he gave one piece of advice:

“Don’t just build machines you can control. Build ones you can understand.”

Today, Aether Dynamics has a new protocol: every new prototype goes through “Reyes Calibration” — a blend of machine logic and human rhythm.

Mateo has returned a few times, but only as a guest. Yet when he enters the hangar, something strange happens.

People fall silent.

Not out of fear, or awe. But out of respect. Because somehow, in an age of AI and automated diagnostics, they witnessed something different.

A boy with no degree heard a machine no one else could.

And the machine?

It listened back.

Epilogue

In a quiet corner of the hangar, a small plaque now hangs above the workstation where VORTEX was reborn.

It reads:

“In memory of Ramon Reyes — who taught us to listen. And to his son, who reminded us why.”